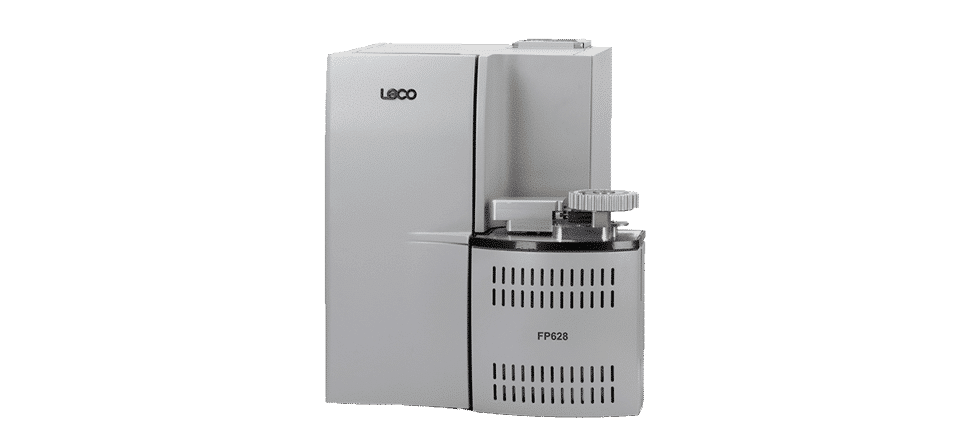

Oxygen/Nitrogen by Inert Gas Fusion Infrared 736 Series

Leco

Contact a technical expert | Dowload the datasheet

Oxygen/Nitrogen by Inert Gas Fusion Infrared and Thermal Conductivity Detection Technique

LECO’s ON736 Oxygen/Nitrogen Elemental Analyzer is designed for routine measurement of oxygen and nitrogen content of inorganic materials, steel, ferrous and nonferrous alloys, and refractory materials using the inert gas fusion technique

Advantages

- Analysis time 100 seconds

- Accuracy and precision to low-ppm levels

- High-Performance LECO detectors assure results quality, drift-free and long-life operation

- Modern Cornerstone software : easy of use with reach functionalities

- Well engineered ergonomics and convenience of use with bench space saving

- Optional auto cleaner minimize need for cleaning between analysis

- Reliable Automation available for increased workload

The ON736 instrument is compliant to ASTM and ISO approved methods. It is perfectly suitable for elemental analysis of reactive/refractory metals, like Titanium, Tantalum, Zirconiumand their alloys.

The instrument features a custom MS Windows®-based software interface designed specifically for touch-screen operation. Developed by combining long-term research with customer feedback, this easy-to-use software gives you complete access to instrument control, analysis settings, diagnostics, reporting, and more—without sacrificing valuable bench space.

- Integral Sample Loading Area minimizes atmospheric contamination during sample introduction

- Jam Free Sample Drop

- Choice of either argon or helium carrier gas

- Novel electrode design increases heat transfer efficiency for increased stability

- High efficiency cooling

- Built in vacuum cleaner keeps working area clean

- Thermostated detector design with built-in drift compensation circuitry