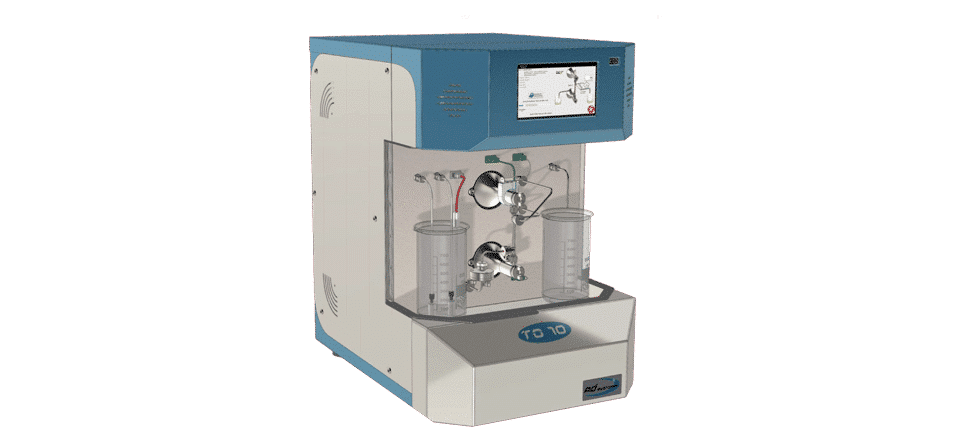

Tube reader DR10

Ad Systems

Contact a technical expert | Dowload the datasheet

Thermal Oxidation Stability of Aviation Turbine Fuels

A new instrumental method of quantitative measurement of tube deposits has been developed by AD Systems, in which the thickness of the deposit is accurately determined by an automatic instrument, reducing test subjectivity.

Advantages

- Quick results

- Compacy

- Easy to use

- Automatic transfer of results to TO10

- Robust and without optical adjustment

Thermal Oxidation Stability of Aviation Turbine Fuels, ASTM D3241 is universally used by the industry to measure high temperature stability of aviation turbine fuels. The ASTM D3241 is required to be run on every batch of jet fuel produced according to ASTM D1655 or DEF STAN 91-91 specifications. In this test method, the fuel is pumped through heater tube at fixed flow rate and during a specified period of time. The fuel is pass or fail rated according to the amount of deposit formed on the heater tube at a specified temperature. Traditionally, the amount of deposit on the tube is rated visually against a reference color scale. The proper rating requires significant experience and expertise. However, operator capabilities vary, so evaluation of color can be quite subjective.

- Dimensions W x D x H (mm): 250 x 160 x 290

W x D x H (inches): 10″ x 16″ x 12″ - Average thickness 10 to 1200 nm

- Maximum thickness 10 to 1200 nm

- Maximum thickness on 2,5 mm² area 10 to 1200 nm

- Deposit volume 0 to 0.5 mm³

- Test duration Less than 15 minutes

- Number of measurement points 1,200 points

- Refineries

- Special fuel

- Pipeline and terminals

- Military fuel testing

- Jet fuel testing

Brochure

Tube reader DR10 (pdf / 565,68 KB)