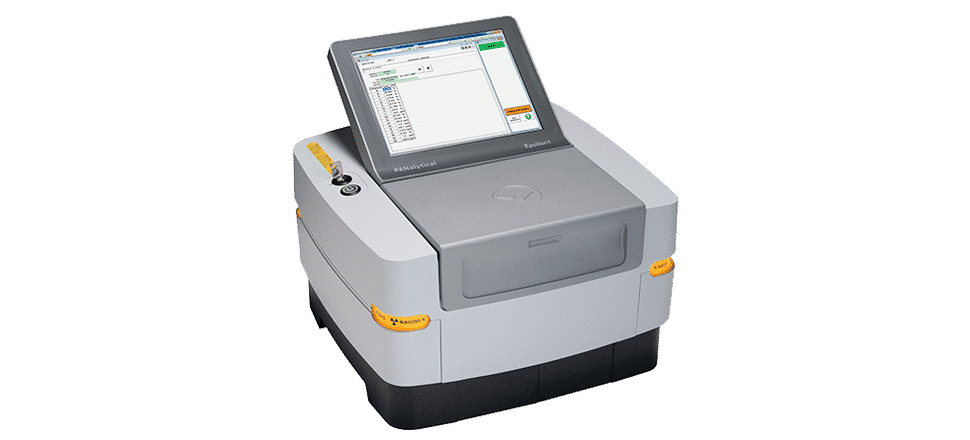

Epsilon 4 Lubricating oils

Malvern panalytical

Value beyond compliance

For the Epsilon 4 the mandated compliancy is merely the starting point ; where the instrument really shines is the additional value it brings for many other analytical tasks in the production of lubricating oils

Advantages

- The power of benchtop XRF

- Guaranteed performance

- Calibrated for years

- Fast and sensitive

- Reduce helium consumption

Epsilon 4 offers excellent performance for elemental analysis in different processes in refineries. This new and powerful benchtop XRF instrument is well suited for the analysis of additives and wear metals in lubricating oils according to the latest relevant international test methods.

Sample handling :

– 10-position removable sample changer

– Typically 5 ml liquid samples

– Spinner is included for better accuracy of air filter analysis

X-ray tube :

– Metal-ceramic side window for maximum stability

– 50 micrometers thin beryllium window for high sensitivity for light elements (Na, Mg, Al, Si)

– Ag anode X-ray tube for best performance of P, S and Cl analysis

Detector :

– High-resolution, typically 135 eV @ Mn-Kα

– Max. count rate of 1,500,000 counts/s at 50% dead time

– Thin-entrance detector window for high sensitivity

Software :

– One flexible calibration for oils and fuels using Oil-Trace

– Elemental screening with Omnian standardless analysis solution

– PASS/FAIL analysis with FingerPrint solution

- Reduce errors of production by positive material identification

- Faster and more accurate dosage of expensive additives

- Supporting optimal blending efficiency of base oils and additives

Brochure

Epsilon 4 Lubricating oils (pdf / 3,88 MB)