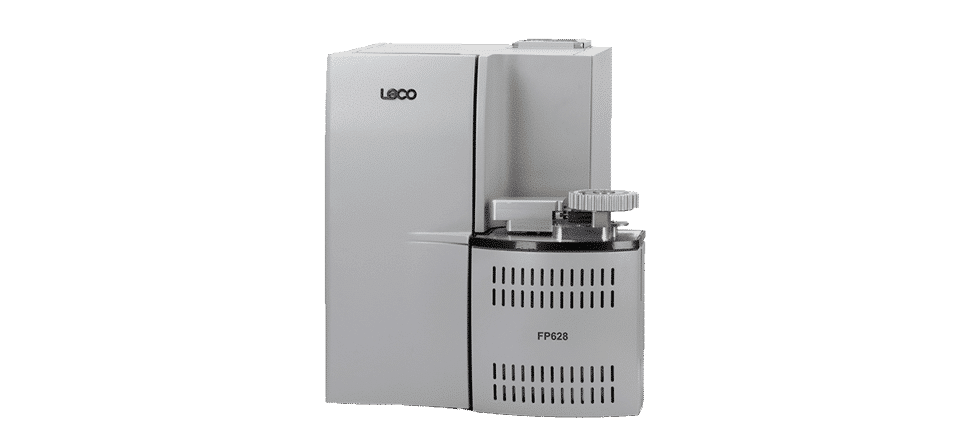

Carbon and Sulfur in Inorganic Materials 844 Series

Leco

Contact a technical expert | Dowload the datasheet

Carbon and Sulfur in Inorganic Materials by the Combustion

LECO combined our customers’ feedback with innovative engineering to develop the CS844, an elemental analyzer designed for wide-range measurement of carbon and sulfur content of primary steels, ores, finished metals, ceramics, and other inorganic materials using the combustion technique.

Advantages

- LECO High-Efficiency Combustion Furnace is perfectly suited for all applications

- State-of-the art IR detection Cell Design for ultimate precision and stability of results

- Modern Cornerstone software : easy of use with reach functionality

- Reliable Automation available for increased workload

- Well engineered ergonomics and convenience of use

The instrument complies with many approved standard test methods, like ISO 9556, ISO 10719, ASTM E1941, ASTM E1019 and many others.

Our exclusive MS Windows®-based software, coupled with a boom-mounted touch interface, gives you complete access to instrument control, analysis settings, diagnostics, reporting, and more—without sacrificing valuable bench space.

High-Efficiency Combustion Furnace

- Combusts a wider variety of samples more efficiently

- Low-maintenance design allows for more frequent analyses without regular cleaning

- Reduces the need for additional accelerant, lowering the cost-per-analysis

Improved IR Cell Design

- Increased precision for more accurate results

- Easily interchangeable, with drop-and-go capabilities

- Increased stability throughout use and lifetime of the cell

- Dual-detector configuration for both carbon and sulfur

Reliable Automation Available

- 10- and 60-position shuttle loaders or integrated robotic process loaders available

- Autoloader is the perfect solution for high-throughput laboratories requiring unattended analyses

- High-efficiency autocleaner/vacuum system keeps maintenance to a minimum

- Automatic combustion tube service and exchange system

Improved ergonomics

- Boom-mounted touch interface for improved ergonomics and intuitive operation

- Pressure-compensated and temperature-controlled gas dose system

- Novel flowpath plumbing minimizes connections to make/break/leak